Techniques and Methods for Connecting Optical Fibers

Connecting optical fibers is a critical process in building high-speed communication networks. Proper fiber connections ensure minimal signal loss and maintain network reliability. Various methods and tools are used depending on the application and fiber type. Understanding these techniques is essential for engineers and technicians. Efficient connections improve performance and reduce maintenance costs.

Mechanical Splicing

Mechanical splicing is a method where fibers are aligned and held together using a mechanical fixture. No heat or fusion is required, making it convenient for field repairs. This technique provides moderate performance and is suitable for temporary connections. Mechanical splices are easy to install and require minimal training. They are often used in emergency or low-cost deployments.

Alignment is critical to minimize signal loss in mechanical splicing. Connectors with precision V-grooves or clamps ensure proper fiber contact. Index-matching gel is commonly used to reduce reflection and insertion loss. Mechanical splicing allows quick deployment in remote areas. Proper handling ensures long-term reliability of the connection.

While convenient, mechanical splicing may not match the performance of fusion splicing. It is sensitive to environmental conditions like temperature and humidity. Regular inspection ensures continued signal integrity. This method is practical for temporary networks or field repairs. Mechanical splicing offers a balance between simplicity and functionality.

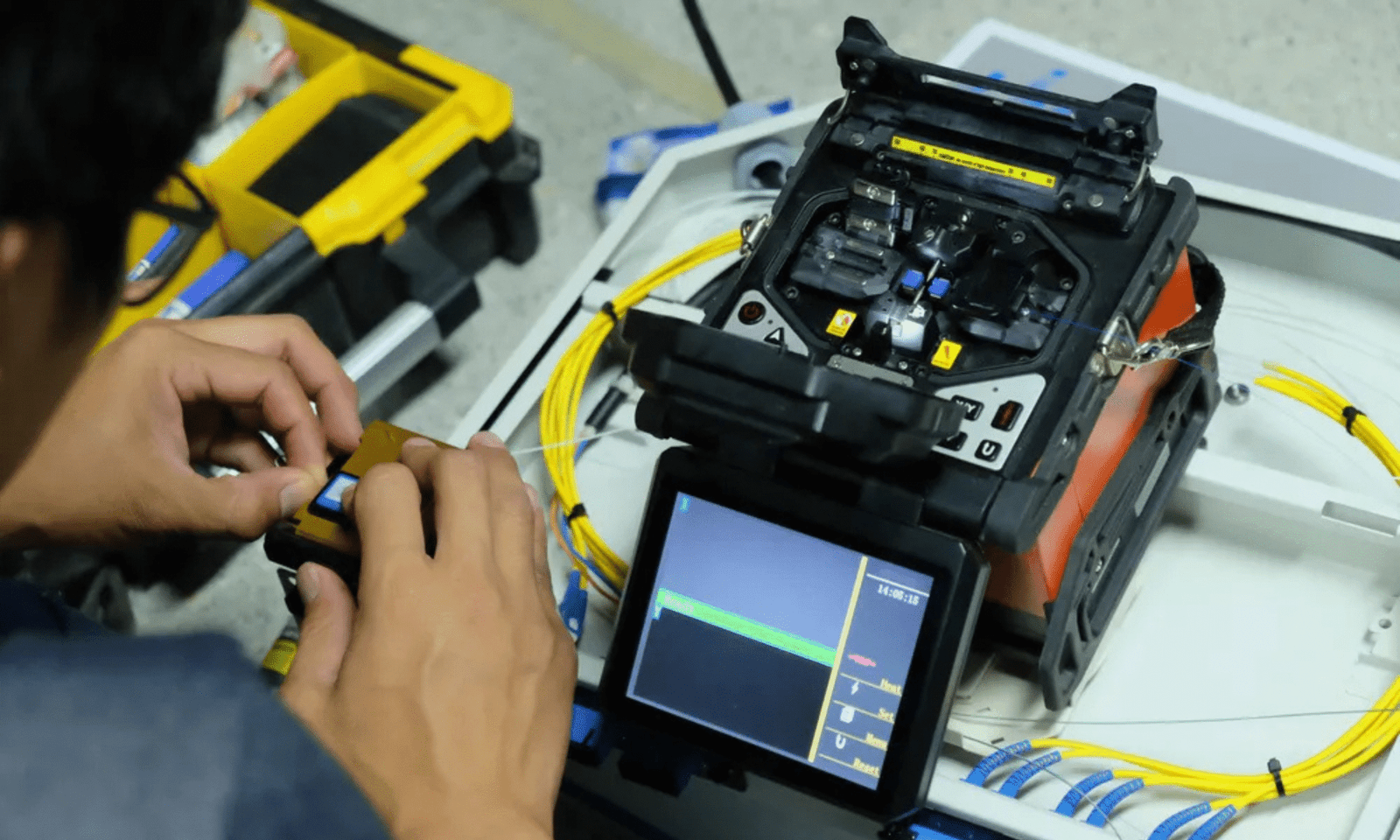

Fusion Splicing

Fusion splicing involves permanently joining fibers using heat, typically from an electric arc. This method provides the lowest insertion loss and strongest connection. Fusion splices are reliable for long-term installations in backbone and distribution networks. Precision splicing machines ensure alignment of fiber cores. Fusion splicing is widely used in professional network deployments.

Preparation is crucial for fusion splicing, including stripping, cleaning, and cleaving the fiber. Misalignment or impurities can increase signal loss significantly. Splice protection sleeves protect the joint from mechanical stress and environmental damage. Skilled operators achieve consistent, high-quality connections. Fusion splicing is considered the gold standard for fiber networks.

Fusion splicing supports single-mode and multi-mode fibers effectively. Advanced machines may include automated core alignment and loss estimation. The process requires proper training and equipment investment. Fusion splices are durable and low-maintenance. They are preferred for critical networks requiring minimal signal degradation.

Fiber Connectors

Fiber connectors allow easy connection and disconnection of optical fibers. Common types include SC, LC, ST, and MPO connectors. They are widely used in patch panels, equipment interfaces, and data centers. Connectors simplify network management and troubleshooting. Proper installation ensures low insertion loss and high repeatability.

Connector performance depends on ferrule quality, polishing technique, and alignment. APC connectors are angled to reduce back reflection in single-mode networks. Multi-fiber connectors like MPO handle high-density applications efficiently. Cleanliness is critical; dust or debris can degrade signal quality. Connectors are essential for modular and flexible network designs.

Maintenance of connectors involves regular cleaning and inspection. Specialized tools and cleaning kits ensure proper contact surfaces. Connector reuse should be minimized to maintain optimal performance. Selecting the right type ensures compatibility with network equipment. Fiber connectors provide flexibility and convenience in optical networks.

Splice Loss and Attenuation

Splice loss refers to signal reduction at the connection point of fibers. Minimizing splice loss is vital for maintaining overall network performance. Both fusion and mechanical splicing methods aim to reduce insertion loss. Proper alignment, cleaving, and polishing are key factors. Network designers account for splice loss in link budgets.

Insertion loss varies depending on fiber type, core alignment, and connector quality. Single-mode fibers require precise alignment due to small core size. Multi-mode fibers tolerate slight misalignment but still benefit from careful splicing. Loss measurements ensure network specifications are met. Reducing splice loss improves data transmission reliability.

Environmental factors like temperature and humidity can affect long-term splice performance. Protective sleeves and enclosures shield splices from stress. Periodic testing identifies potential issues before service impact occurs. Proper training and techniques maintain low splice loss throughout the network. Effective splice management ensures efficient optical communication.

Alignment Techniques

Accurate fiber alignment is critical for low-loss connections. Core-to-core alignment ensures maximum light transfer between fibers. V-groove fixtures, precision sleeves, and fusion splicing machines aid alignment. Misalignment can lead to high attenuation and signal degradation. Alignment techniques vary depending on fiber type and splicing method.

Active alignment uses live signal monitoring to optimize connection. It ensures minimal loss and reflection during installation. Passive alignment relies on precise mechanical components and tolerances. Single-mode fibers demand more precise alignment than multi-mode fibers. Correct alignment directly impacts the quality of the optical link.

Automated alignment features in modern splicing machines improve consistency. Technicians can achieve high repeatability with minimal manual adjustment. Alignment quality is verified using optical time-domain reflectometers (OTDR). Proper technique reduces installation errors and long-term maintenance. Accurate alignment is the foundation of reliable optical networks.

Environmental Protection

Fiber connections are sensitive to physical stress and environmental conditions. Protective enclosures and sleeves safeguard splices and connectors. Outdoor installations may require weatherproof boxes and gel-filled closures. Environmental protection ensures long-term performance. It also reduces maintenance frequency and network downtime.

Cables and joints are secured to prevent bending, pulling, or crushing. Temperature fluctuations can affect mechanical splices, so proper insulation is important. Humidity-resistant materials protect connectors and splices. Environmental considerations are critical for aerial, underground, and outside-plant networks. Protection strategies extend the lifespan of fiber connections.

Routine inspections check for physical damage and water ingress. Maintenance crews replace compromised enclosures promptly. Proper sealing prevents dust and debris accumulation. Fiber routing and fixation techniques reduce stress on the connections. Environmental protection is essential for high-reliability optical networks.

Testing and Verification

Testing verifies the quality and performance of fiber connections. Common methods include OTDR testing, power meter measurements, and visual inspection. Testing ensures minimal splice loss, proper alignment, and connector integrity. It identifies faults or defects before network activation. Regular verification maintains service quality over time.

OTDR testing maps fiber routes and locates losses or breaks. Power meters measure end-to-end attenuation accurately. Visual inspection helps detect contamination or misalignment in connectors. Testing is mandatory for both new installations and repairs. Proper test procedures validate network reliability.

Advanced testing equipment provides automated reporting and data logging. Technicians can monitor trends and predict maintenance needs. Testing protocols differ for single-mode and multi-mode networks. Verified connections minimize troubleshooting after deployment. Routine testing is essential for professional optical network management.

Fiber Optic Patch Panels

Patch panels organize fiber connections in structured cabling environments. They facilitate easy access, management, and routing of multiple fibers. Panels improve network scalability and simplify maintenance. Proper labeling and documentation ensure efficient troubleshooting. Patch panels are standard in data centers and telecom facilities.

High-density patch panels support MPO or LC connectors for compact installations. They allow rearrangement of fibers without disturbing the network. Panels also provide strain relief to protect connectors and splices. Modular designs enhance flexibility for growing networks. Patch panels centralize fiber management efficiently.

Installation requires proper cable management and routing practices. Protective trays prevent bending and damage to fiber cables. Panels must accommodate both current and future capacity needs. Clean and organized patch panels reduce errors during maintenance. They are key components of professional fiber optic infrastructure.

Multi-Fiber and Ribbon Fiber Connections

Multi-fiber and ribbon fibers increase network density and efficiency. Ribbon fibers contain multiple cores in a single flat cable for mass fusion splicing. They are common in high-capacity backbone and data center networks. Multi-fiber solutions reduce installation time and space requirements. These fibers support rapid expansion of optical infrastructure.

Specialized fusion splicing equipment handles ribbon fibers efficiently. Alignment is critical to minimize loss across all cores. Ribbon fibers are often pre-terminated or factory-tested for performance. High-density connections meet growing bandwidth demands. Multi-fiber solutions are essential for modern high-speed networks.

Ribbon fiber technology improves cost-effectiveness in large-scale deployments. It simplifies cabling and reduces labor. Multi-fiber connections also enhance signal consistency. Proper handling ensures long-term reliability and minimal maintenance. These connections are central to scalable optical network design.

Future Trends in Fiber Connections

Advances in fiber optic technology continue to improve connection techniques. Innovations include faster fusion splicers, automated alignment systems, and high-density connectors. AI-assisted testing and monitoring enhance efficiency. Future networks demand ultra-low loss and high-capacity connections. Emerging trends aim to simplify installation while maximizing performance.

New connector designs reduce insertion loss and back reflection. High-density solutions support growing data center and metro network requirements. Environmental resilience and modularity are emphasized for network longevity. Automation reduces human error in field deployments. Fiber connection technology continues evolving to meet next-generation communication needs.

Integration with hybrid fiber-wireless networks is becoming common. Fiber connections support 5G backhaul and IoT expansion. Faster, more reliable connections enable advanced services. Network operators prioritize scalability and maintainability. Future optical networks will depend on smarter, easier fiber connection methods.

FAQs

What is the difference between fusion and mechanical splicing?

Fusion splicing permanently joins fibers using heat, offering low loss and high reliability. Mechanical splicing aligns fibers in a fixture without heat, suitable for temporary or low-cost connections. Fusion splicing is preferred for long-term networks. Mechanical splicing is convenient for field repairs. Both methods require proper alignment and handling.

How do fiber connectors affect network performance?

Connectors provide modular, repeatable connections for easy management. Poor connector quality or dirty surfaces increases insertion loss and reflection. APC connectors reduce back reflection in single-mode networks. Proper installation and maintenance ensure minimal signal degradation. Connectors are essential for flexible and scalable networks.

What is splice loss and why is it important?

Splice loss is the reduction of signal strength at the fiber joint. Minimizing splice loss ensures efficient data transmission. High splice loss can degrade network performance and cause errors. Both fusion and mechanical splices aim to keep loss low. Proper techniques and protection maintain low splice loss over time.

How are ribbon fibers different from standard fibers?

Ribbon fibers contain multiple cores in a flat cable for mass splicing. They increase network density and reduce installation time. Standard fibers typically have a single core per cable. Ribbon fibers are ideal for high-capacity backbones and data centers. They require specialized splicing equipment for optimal performance.

What protective measures ensure fiber connection longevity?

Environmental enclosures, protective sleeves, and strain relief reduce stress and damage. Weatherproof and dust-resistant materials safeguard outdoor connections. Proper cable routing and fixation prevent bending or crushing. Regular inspection and maintenance identify issues early. Protection ensures long-term reliability and network stability.