Essential Tools and Equipment for Setting Up a Service Center

Setting up a service center requires careful planning and the right tools to ensure efficiency and customer satisfaction. The quality of equipment directly impacts service quality and operational workflow. From basic hand tools to advanced diagnostic machines, every component plays a critical role. Understanding what to invest in helps streamline operations. Proper tools also ensure safety, reliability, and long-term productivity.

Workbenches and Furniture

Workbenches provide a stable and organized workspace for service tasks. Durable benches with storage compartments improve efficiency. Ergonomic chairs and adjustable tables enhance comfort for staff. Proper lighting and layout support productivity and reduce errors. Choosing the right furniture is foundational for a functional service center.

Benches with integrated tool racks keep essential equipment within reach. Anti-static mats protect sensitive electronics from damage. Modular furniture allows reconfiguration as the workflow evolves. Space planning ensures smooth movement between service stations. Quality furniture supports both staff and workflow efficiency.

Ergonomics are important to reduce fatigue during long working hours. Adjustable heights accommodate various tasks and staff preferences. Shelving units and cabinets organize spare parts and accessories. A clutter-free workspace improves focus and reduces mistakes. Investing in durable and functional furniture sets the tone for a professional service center.

Hand Tools

Hand tools are essential for routine repairs and maintenance. Screwdrivers, pliers, wrenches, and cutters form the basic toolkit. Precision tools are required for electronics or delicate components. Quality hand tools increase efficiency and reduce the risk of damaging parts. Investing in a comprehensive set ensures readiness for varied tasks.

Specialized hand tools, such as torque wrenches and hex keys, support specific service operations. Anti-slip grips and insulated handles improve safety. Organization in tool storage reduces time spent searching for equipment. High-quality hand tools are more durable and maintain performance over time. They are a cost-effective investment for any service center.

Regular maintenance of hand tools extends their lifespan. Cleaning and proper storage prevent rust and wear. Staff training ensures tools are used correctly to maximize effectiveness. Ergonomically designed tools reduce strain during repetitive tasks. A well-stocked hand tool set forms the backbone of service operations.

Power Tools

Power tools speed up tasks and handle heavy-duty jobs efficiently. Drills, grinders, and electric screwdrivers reduce manual effort. Cordless models enhance mobility in large service areas. Proper power tools improve productivity and precision. Safety features like overload protection are crucial during operation.

Impact drivers and rotary tools allow fast disassembly and reassembly of equipment. Bench-mounted power tools, such as saws and drills, support fabrication or repair tasks. Choosing reliable brands ensures long-term performance and durability. Regular inspection prevents malfunction and accidents. Power tools complement hand tools for versatile service operations.

Maintenance of power tools involves cleaning, lubrication, and battery care for cordless devices. Staff should follow safety protocols and wear protective gear. Organized storage prevents damage and prolongs tool life. Selecting the right power tools depends on the type of services offered. Efficient tools save time and improve service quality.

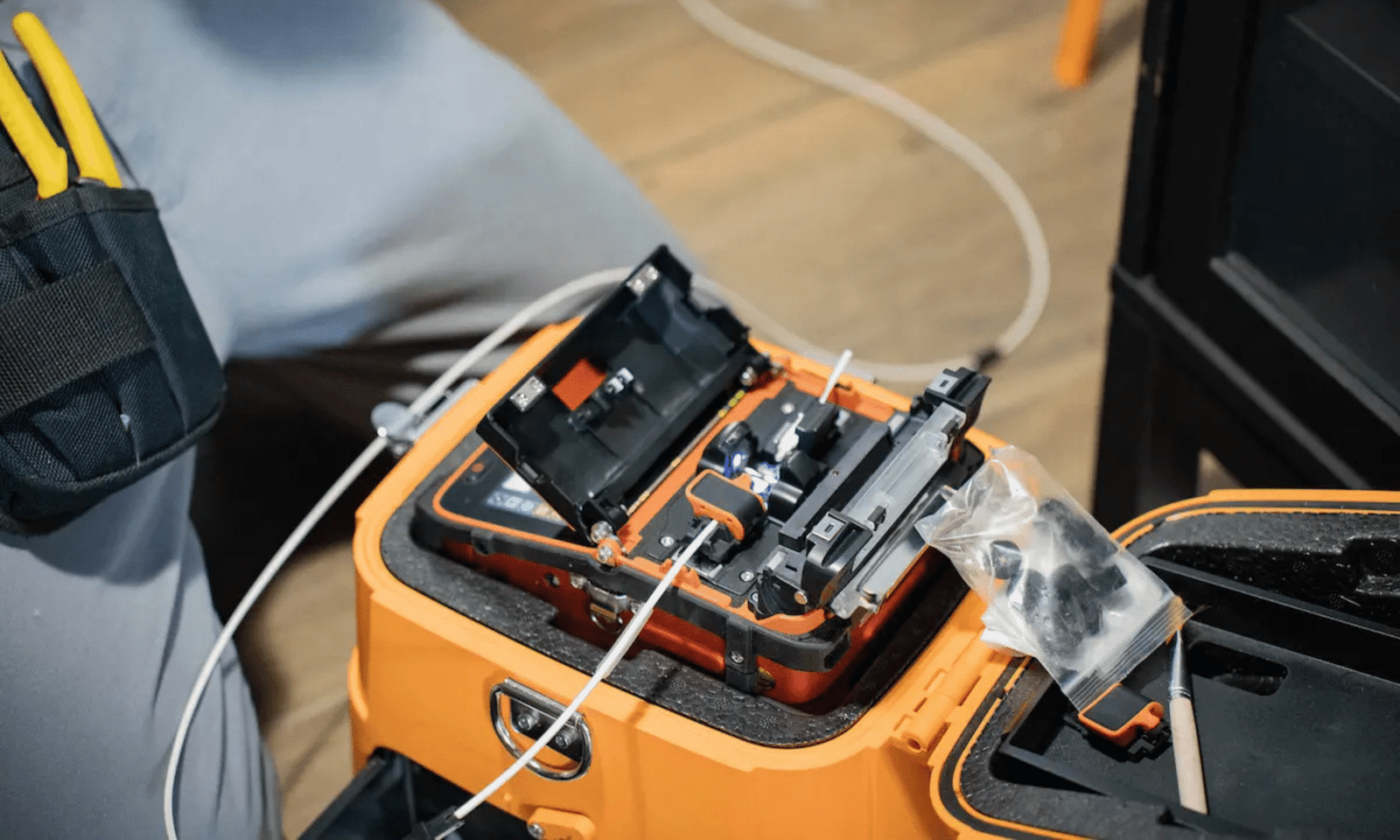

Diagnostic and Testing Equipment

Diagnostic equipment is crucial for identifying issues accurately. Multimeters, oscilloscopes, and specialized testers detect electrical and mechanical problems. Modern devices may include software for detailed analysis. Accurate diagnostics prevent unnecessary repairs and reduce service time. High-quality testing tools increase customer trust.

Testing tools support various components, including circuits, batteries, and mechanical parts. Portable devices allow on-the-spot diagnostics. Calibration ensures reliable readings and reduces errors. Integration with digital systems allows record-keeping and monitoring. Reliable testing equipment is essential for professional service centers.

Routine checks of diagnostic tools maintain accuracy and longevity. Protective cases prevent damage during storage and transport. Staff training ensures proper usage and interpretation of results. Investing in advanced diagnostic equipment enhances the service center’s capabilities. Efficient testing reduces downtime and improves service satisfaction.

Computer and Software Systems

Computers and software manage service records, inventory, and scheduling. Specialized management software tracks customer requests and repair history. Integration with diagnostic tools improves efficiency and reporting. Digital systems enhance communication and workflow management. Proper IT infrastructure supports smooth service operations.

Software solutions may include billing, invoicing, and warranty management. Cloud-based systems allow remote access and centralized data storage. Security measures protect customer information and service records. User-friendly interfaces reduce training time for staff. Efficient software systems streamline administrative and technical processes.

Regular updates and maintenance ensure software reliability. Backup systems prevent data loss in case of failures. Staff should be trained in both hardware and software operations. Modern service centers rely on integrated systems for efficiency and accuracy. Computer systems enhance both operational and customer service aspects.

Lifting and Handling Equipment

Lifting equipment aids in handling heavy machinery or vehicles safely. Hydraulic lifts, jacks, and hoists reduce physical strain on staff. Proper equipment prevents accidents and equipment damage. Ergonomic handling improves workflow and productivity. Investing in reliable lifting tools ensures workplace safety.

Adjustable lifts accommodate different sizes of machinery or vehicles. Safety locks and load limits prevent accidents during operation. Portable lifting devices increase flexibility in large service centers. Training ensures staff use lifting equipment correctly. Efficient handling equipment saves time and protects staff and assets.

Maintenance of lifting devices is critical for safety. Regular inspection of hydraulics, bolts, and safety mechanisms prevents failures. Lubrication and cleaning extend equipment lifespan. Compliance with safety regulations is essential to avoid workplace hazards. Proper handling tools protect both personnel and machinery.

Storage and Organization

Organized storage keeps tools, parts, and supplies easily accessible. Shelving units, bins, and cabinets reduce clutter. Labeling and categorization improve workflow efficiency. Proper storage protects tools from damage and prolongs their lifespan. Efficient organization enhances overall productivity in the service center.

Parts storage systems prevent loss and simplify inventory management. Modular storage allows reconfiguration as needs change. Safety storage is important for flammable or hazardous materials. Quick access to components reduces downtime during repairs. Well-organized storage ensures smooth service operations.

Regular audits maintain organization and prevent overstocking or shortages. Clean and accessible storage areas promote a professional environment. Staff training encourages consistent use of organizational systems. Proper storage reduces operational errors and improves turnaround time. A structured storage system supports a high-functioning service center.

Safety and Protective Equipment

Safety equipment protects staff from potential hazards. Gloves, goggles, masks, and anti-static wrist straps prevent injury during operations. Fire extinguishers, first aid kits, and emergency signage enhance workplace safety. A safe environment reduces accidents and boosts confidence. Compliance with safety standards is essential.

Protective clothing shields workers from heat, chemicals, or electrical hazards. Proper ventilation and fume extraction prevent respiratory issues. Safety protocols ensure equipment is used correctly and responsibly. Training on emergency procedures is essential for all staff. Safety equipment contributes to long-term operational stability.

Routine checks ensure safety gear and devices function properly. Replacement of worn or expired items maintains protection. Safety culture encourages staff to follow guidelines consistently. Investing in high-quality protective equipment is a cost-effective preventive measure. Workplace safety is a core component of service center management.

Communication and Networking Tools

Efficient communication is vital for coordinating tasks and serving customers. Phones, intercoms, and wireless devices support internal and external communication. Networking equipment connects computers, software, and diagnostic systems. Reliable connectivity ensures smooth operations and data sharing. Communication tools enhance both efficiency and customer satisfaction.

Networking devices like routers, switches, and access points maintain system integration. Cloud connectivity allows remote monitoring and service tracking. Collaboration tools facilitate teamwork among technicians. Proper cabling and network security prevent downtime and breaches. Effective communication systems streamline service center workflow.

Regular network maintenance ensures continuous connectivity. Staff should be trained to troubleshoot basic network issues. Wireless and wired options provide flexibility depending on infrastructure. Integration with management software supports operational efficiency. Communication and networking tools are the backbone of modern service centers.

Cleaning and Maintenance Supplies

Keeping a service center clean improves safety and professionalism. Cleaning agents, microfiber cloths, and vacuums maintain tools, equipment, and workspaces. Regular maintenance of machines prevents breakdowns and prolongs their life. Clean environments reduce contamination risks for sensitive components. Consistent upkeep supports operational efficiency.

Maintenance supplies include lubricants, oils, and calibration tools. Proper cleaning of electronic and mechanical parts ensures accurate operation. Scheduled maintenance routines prevent unexpected downtime. Staff should follow guidelines for using cleaning and maintenance products. Regular upkeep protects both equipment and staff.

Organized storage of cleaning supplies ensures accessibility and prevents accidents. Protective gear should be used when handling chemicals or cleaning agents. Documentation of maintenance schedules ensures tasks are not overlooked. Investment in quality cleaning and maintenance supplies enhances overall service quality. A well-maintained center operates smoothly and safely.

FAQs

What are the essential tools for a basic service center?

Essential tools include hand tools like screwdrivers, pliers, wrenches, diagnostic devices, and safety equipment. Basic furniture like workbenches and chairs is also necessary. Power tools and storage solutions improve efficiency. Selecting quality tools ensures reliability and reduces long-term costs. A well-equipped toolkit forms the foundation of operations.

How important is diagnostic equipment in a service center?

Diagnostic equipment ensures accurate detection of issues, saving time and preventing unnecessary repairs. Multimeters, oscilloscopes, and specialized testers improve service quality. Proper diagnostics increase customer trust. Regular calibration maintains accuracy. High-quality testing equipment is critical for professional service centers.

What safety measures should be implemented?

Safety gloves, goggles, masks, anti-static straps, and proper ventilation protect staff. Fire extinguishers, first aid kits, and emergency signage are essential. Training on protocols reduces accidents. Regular inspection and replacement of protective equipment ensure continued safety. Compliance with safety regulations is mandatory.

How should tools and parts be organized?

Use shelving units, bins, cabinets, and labeling for systematic storage. Modular organization allows flexibility for evolving needs. Proper storage reduces clutter, prevents damage, and improves workflow. Inventory checks prevent shortages or overstocking. Organized tools and parts enhance operational efficiency.

Which equipment is essential for heavy-duty tasks?

Lifting equipment such as hydraulic jacks, hoists, and adjustable lifts are essential. Power tools like drills, grinders, and electric screwdrivers reduce manual effort. Ergonomic workbenches and proper handling gear protect staff. Regular maintenance ensures safety and durability. Heavy-duty tools improve productivity and efficiency.